Blister Card Packaging

Blister card packaging boxes have become increasingly popular in recent years. The versatility and durability of blister card packaging make it an ideal solution for companies looking to promote their products while keeping them protected.

The blister cards also provide a transparent view of the product, enabling consumers to see what they are purchasing without opening the package.

These boxes are a popular choice for various industries, including retail, pharmaceutical, and electronic. They are commonly used for packaging small and lightweight items, making them a popular choice for products like small electronics and toys.

Get Quote

Material

Foil/Metallic Card Stock

An endless variety to give a luxurious look on the top side to make a metallic surface

Kraft/Brown Card Stock

Made with 100% environment-friendly material, this collection gives more printing options along with sustainability

Textured Card Stock

From 12pt – 24pt end C1S or C2S white paper board, it gives more printing options for customization

White Card Stock

A soft and uncoated stock offers a unique and textured look to give a rich feel

Specifications

- Size: Available in all shapes and sizes

- Stock: 14pt, 16pt, 18pt and 24pt White SBS C1S C2S

- Finishing options: Gloss, Matte, Aqueous Coating, Spot UV

- Add on choices: Available in all shapes and sizes

When it comes to retail packaging, blister card packaging boxes have become increasingly popular in recent years. The versatility and durability of blister card packaging make it an ideal solution for companies looking to promote their products while keeping them protected. The blister cards also provide a transparent view of the product, enabling consumers to see what they are purchasing without opening the package.

These boxes offer a range of benefits such as protection from damage during transport or storage, ease of use with easy-open tabs or tear notches, and ample branding opportunities. With custom printing options available for both the cardboard backing and plastic blister you can rest assured that your boxes are one of the best in the market.

What are Blister Card Packaging Boxes?

Blister card packaging boxes are made up of a plastic blister or bubble that is sealed onto a cardboard backing. This packaging solution is commonly used for small consumer products such as electronics, toys, and pharmaceuticals. These boxes are a popular choice for various industries, including retail, pharmaceutical, and electronic. They are commonly used for packaging small and lightweight items, making them a popular choice for products like small electronics and toys. Blister card packaging is also used in the pharmaceutical industry to package individual pills, capsules, and tablets.

The Unbeatable Choice: Our Blister Card Packaging Boxes

Protection and Durability

Blister card boxes are designed to keep products safe during transportation, storage, and display. The plastic blister provides a barrier between the product and the outside environment, preventing damage from moisture, dust, and other elements. The cardboard backing also provides an additional layer of protection, ensuring that the product remains intact during transportation.

Visibility and Merchandising

Blister card packaging boxes offer a clear window for customers to view the product, making them an excellent choice for merchandising. The clear blister allows customers to see the product without having to open the package, which is particularly useful for products that are expensive or prone to damage. The cardboard backing also provides a surface for branding and product information, making it an effective marketing tool.

Cost-Effective Packaging Solution

These boxes are a cost-effective packaging solution, particularly for smaller products. The materials used in blister card packaging are relatively inexpensive, and the manufacturing process is straightforward, making it an affordable option for companies looking to save on packaging costs.

The Art of Crafting Premium-Grade Blister Card Packaging Boxes

Design Phase

The first stage in our manufacturing process is the design phase. Our team of designers works closely with clients to create a design that meets their specific needs. We take into account the product to be packaged, the target audience, and any branding guidelines provided by the client.

Material Selection

The next stage is material selection. We work with various materials, including PVC and PET for blisters and different grades of cardboard for the backing. We take into account the product to be packaged, the intended use of the packaging, and the client’s budget when selecting the materials.

Blister Card Formation

Once the design and materials have been selected, we move on to the blister card formation stage. The plastic blisters are formed using vacuum thermoforming, and the cardboard backing is cut to the appropriate size and shape.

Printing and Finishing

The final stage is printing and finishing. We use advanced printing techniques to ensure that the packaging is of high quality and accurately reflects the client’s branding. We also offer various finishing options, including embossing, debossing, and foil stamping.

Why Our Blister Card Packaging Boxes Outclass the Competition

- Size and Shape: We offer various sizes and shapes of blister card packaging boxes to suit different products and applications. Our team of designers can work with clients to create a custom size and shape that meets their specific needs.

- Printing and Graphics: We offer advanced printing techniques that allow us to print high-quality graphics and branding onto blister card packaging boxes. We can print in full color and offer various finishing options, including embossing, debossing, and foil stamping.

- Materials and Thickness: We offer various materials and thicknesses to suit different products and applications. We can work with clients to select the appropriate materials and thicknesses for their specific needs.

- Quality Assurance and Testing: At our manufacturing facility, we take quality assurance seriously. Our blister card packaging boxes undergo rigorous testing to ensure they meet the highest standards.

- ISO Certification and Compliance: We are proud to be ISO certified and compliant with all industry and regulatory requirements. This certification reflects our commitment to producing high-quality custom blister card packaging boxes that comply with all safety and environmental standards.

- Testing for Strength and Functionality: Our products undergo extensive testing to ensure that they are strong and functional. Our quality assurance team tests each box using a variety of methods to ensure that they can withstand the rigors of shipping and handling. We also test the functionality of our boxes to ensure that they are easy to open and use.

Why Choose Us for Your Blister Card Packaging Needs

We understand that you have many options when it comes to selecting a supplier for your blister card packaging needs. Here are just a few reasons why you should choose us:

- Years of Experience in the Industry

We have been manufacturing wholesale blister card packaging boxes for many years and have gained valuable industry experience. Our team is highly knowledgeable and passionate about delivering quality products and excellent customer service.

- Customer Satisfaction and Testimonials

Our commitment to customer satisfaction is evident in the testimonials we receive from our customers. We pride ourselves on building long-term relationships with our customers and are always happy to hear their feedback.

- Flexibility and Customization Options

We understand that every customer has unique requirements when it comes to their blister card packaging needs. That’s why we offer customization options that allow our customers to select the best packaging solution that fits their specific requirements.

Premium Finishing

Embossing/Debossing

Embossing and debossing create either raised or recessed images and designs in different materials, including paper.

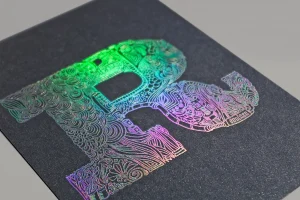

Foiling

A process to add a luxurious finish to the marketing materials covering a wide range of colors to create an eye-catchy look

Gloss Lamination

To enhance durability, a protective glass lamination is applied that also gives a shiny and textured appearance

Holographic Foiling

An embossed pattern foiling gives colors of the spectrum at different angles to create a classy style

Free Design Consultation

Schedule a Free Consultation & Share Your Ideas to Create a Modern Design

Let’s Start to Bring a Change

We understand how important it is to get effective packaging design to create a lasting impression & improve customer retention in your business. Our professionals are here for Free Design Consultation & help you bring your vision to life.

You’re in good hands, just come and share your ideas on how you want your packaging, and our designers will help with the best solutions. They will guide you on each step of creating aesthetic designs.

Enjoy Enhanced Ordering

—- Client Feedback —-

Lets Know What Our Client Says About Us

Discover why we’re the top choice in the Packaging Industry.

So comfy and great!

Blythe

Great quality!

Albert

Awesome Design!

Ainsley Barnas

Interior Designer

Bilal